Hey there, craft enthusiasts! If you're diving into the world of painting powder coat, you've come to the right place. This isn't just another DIY guide; it's a deep dive into the art and science of powder coating. Whether you're a seasoned pro or a curious beginner, this article will give you all the tools you need to master the craft. So, buckle up and let's get started!

Now, before we dive headfirst into the nitty-gritty, let's talk about why painting powder coat has become such a big deal. It's not just about aesthetics—though, let's be honest, the finishes are killer. But there's so much more to it. This method offers unmatched durability, versatility, and eco-friendliness. Yep, you heard that right—eco-friendly!

In this article, we'll break down everything you need to know about painting powder coat, from the basics to advanced techniques. We'll also share some insider tips, tricks, and the latest trends to help you level up your skills. So, whether you're painting a bike frame, restoring old furniture, or revamping industrial equipment, this guide's got you covered!

Read also:Narcissistic Mother Quotes Unveiling The Depths Of Toxic Relationships

Table of Contents

- What is Powder Coating?

- Benefits of Powder Coating

- Types of Powder Coating

- Preparation Process

- Application Methods

- Curing Process

- Common Mistakes to Avoid

- Tools and Equipment

- Cost Considerations

- FAQ About Powder Coating

What is Powder Coating?

Alright, let's start with the basics. Painting powder coat isn't your average paint job. Instead of liquid paint, this process uses a dry powder that's electrostatically applied to a surface and then cured under heat. The result? A super-durable, chip-resistant, and weatherproof finish that lasts for years. No wonder it's become the go-to choice for everything from automotive parts to outdoor furniture.

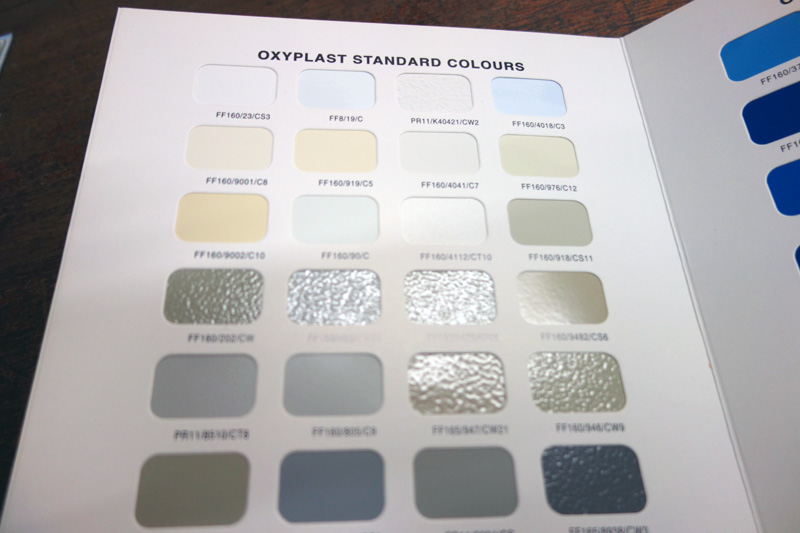

But here's the kicker: unlike traditional painting, powder coating doesn't involve solvents, which means fewer harmful emissions. That makes it a win-win for both your project and the planet. Plus, the range of colors and textures available is insane. From glossy finishes to matte and textured looks, you can basically create anything you dream up.

How Does Powder Coating Work?

Let's break it down step by step. First, the powder is applied using an electrostatic spray gun, which gives the particles a positive charge. The object you're coating gets a negative charge, so the powder sticks to it like magnets. Once the surface is evenly coated, it goes into an oven where the powder melts and forms a smooth, hard layer. Voila! You've got yourself a flawless finish.

Benefits of Powder Coating

So, why should you consider painting powder coat over traditional methods? Let's dive into the top advantages:

- Durability: Powder coatings are built to last. They resist chipping, fading, and corrosion, making them perfect for high-traffic areas and harsh environments.

- Versatility: From metals to ceramics and even plastics, powder coating can be applied to a wide range of materials.

- Eco-Friendly: With no volatile organic compounds (VOCs), powder coating is a safer and greener option for both you and the environment.

- Cost-Effective: While the initial setup might be a bit pricier, the long-term savings in maintenance and longevity make it a smart investment.

- Customization: With endless color and texture options, you can truly make your project stand out.

And let's not forget the wow factor. A well-executed powder coating job can transform even the dullest objects into show-stopping pieces. Who wouldn't want that?

Types of Powder Coating

Not all powders are created equal. Depending on your project's needs, you'll want to choose the right type of powder coating. Here's a quick rundown:

Read also:Remington 870 Police The Backbone Of Law Enforcement

Thermoset Powder Coatings

These are the heavyweights of the powder coating world. Thermoset powders undergo a chemical reaction during the curing process, forming a durable and long-lasting finish. They're ideal for outdoor applications where durability and weather resistance are key.

Thermoplastic Powder Coatings

On the flip side, thermoplastic powders don't undergo a chemical change during curing. Instead, they melt and fuse together, creating a flexible and impact-resistant finish. This makes them great for projects that require a bit of give, like pipes and fittings.

Hybrid Powder Coatings

For those who want the best of both worlds, hybrid powders combine the strengths of thermoset and thermoplastic coatings. They offer excellent adhesion, flexibility, and resistance to chemicals and abrasion.

Preparation Process

Preparation is key when it comes to painting powder coat. A clean and properly prepped surface ensures that the powder adheres evenly and lasts longer. Here's how you can prep like a pro:

- Cleaning: Remove any dirt, grease, or rust from the surface using a degreaser or sandblasting. A clean canvas is essential for a flawless finish.

- Masking: Use masking tape or plugs to cover any areas you don't want coated. This will save you a lot of headache later on.

- Surface Treatment: Depending on the material, you might need to apply a primer or conversion coating to improve adhesion and corrosion resistance.

Remember, the better your prep game, the better your final result. Don't rush this step—it's worth the extra time and effort.

Application Methods

Now that your surface is ready, it's time to apply the powder. There are several methods you can use, depending on your tools and experience level:

Electrostatic Spray

This is the most common method for painting powder coat. Using an electrostatic spray gun, you apply the powder evenly across the surface. The electrostatic charge helps the powder stick to the object, ensuring a uniform coating.

Fluidized Bed Coating

For thicker coatings, fluidized bed coating is the way to go. In this method, the object is preheated and then dipped into a bath of fluidized powder. The heat causes the powder to melt and adhere to the surface.

Tribocharging

Tribocharging is a variation of the electrostatic method where the powder is charged by friction instead of voltage. This method is often used for more delicate or intricate objects.

Curing Process

Once the powder is applied, it's time to cure it. Curing is the process where the powder melts and forms a hard, durable finish. Here's how it works:

- Oven Curing: The coated object is placed in a curing oven at a specific temperature for a set amount of time. This allows the powder to melt, flow, and harden into its final form.

- Infrared Curing: For smaller or more delicate objects, infrared curing can be a faster and more energy-efficient option. It uses infrared radiation to heat the powder directly.

Pro tip: Always follow the manufacturer's curing guidelines to ensure the best results. Skipping or rushing this step can lead to a subpar finish.

Common Mistakes to Avoid

Even the best of us make mistakes sometimes. Here are a few common pitfalls to watch out for when painting powder coat:

- Inadequate Surface Prep: Skipping the cleaning or masking steps can lead to uneven coverage and poor adhesion.

- Incorrect Powder Application: Applying too much or too little powder can affect the final finish. Practice makes perfect here.

- Improper Curing: Under-curing or over-curing can ruin your project. Stick to the recommended curing times and temperatures.

- Ignoring Safety Precautions: Always wear the right protective gear and work in a well-ventilated area to avoid inhaling powder particles.

By avoiding these common mistakes, you'll be well on your way to creating professional-quality finishes every time.

Tools and Equipment

Having the right tools and equipment is crucial for successful painting powder coat. Here's a list of essentials you'll need:

- Spray Gun: Choose a high-quality electrostatic spray gun for even powder application.

- Curing Oven: A reliable curing oven is a must for achieving durable and long-lasting finishes.

- Sandblaster: For cleaning and preparing metal surfaces, a sandblaster can save you tons of time and effort.

- Protective Gear: Don't forget your gloves, mask, and safety goggles to keep yourself safe while working.

Investing in good-quality tools will not only make your job easier but also improve the overall quality of your work.

Cost Considerations

Let's talk money. While painting powder coat can be a bit more expensive upfront compared to traditional painting, the long-term benefits often outweigh the costs. Here are some factors to consider:

- Material Costs: The type of powder and the complexity of the project will affect the material costs.

- Equipment Costs: If you're doing this as a hobby, you might already have some of the necessary tools. Otherwise, purchasing or renting equipment can add to the expenses.

- Labor Costs: If you're hiring a professional, labor costs will vary depending on the size and scope of the project.

Keep in mind that the durability and low maintenance of powder coatings can save you money in the long run. Plus, the stunning results are totally worth it!

FAQ About Powder Coating

Still have questions? We've got answers. Here are some frequently asked questions about painting powder coat:

Can I powder coat at home?

Absolutely! With the right equipment and a little practice, you can definitely powder coat at home. Just make sure you have a well-ventilated area and follow all safety precautions.

What surfaces can be powder coated?

Most metals, ceramics, and some plastics can be powder coated. It's important to choose the right type of powder and prep method for each material.

How long does powder coating last?

With proper care, powder coatings can last anywhere from 10 to 20 years. Factors like exposure to weather and wear and tear can affect longevity.

Is powder coating eco-friendly?

Yes! Powder coatings are free from VOCs and can be recycled, making them a much greener option than traditional paints.

Conclusion

And there you have it—a comprehensive guide to painting powder coat. From understanding the basics to mastering the techniques, we hope this article has equipped you with the knowledge and confidence to take on your next project. Remember, practice makes perfect, so don't be afraid to experiment and find what works best for you.

Now, it's your turn! Share your experiences, ask questions, or show off your powder coating creations in the comments below. And if you found this article helpful, don't forget to share it with your fellow craft enthusiasts. Happy coating, and see you on the next project!